In Part 1, we decided to make a calendar this year!

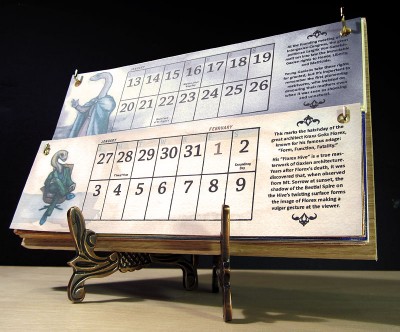

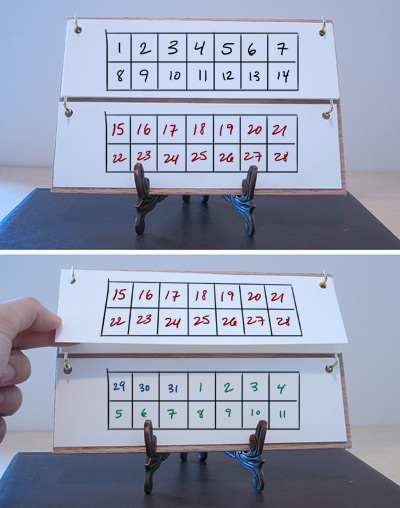

In Part 2, we discussed the layout and format of the calendar — 27 biweekly cards in a modular, hook-based format AKA the future standard.

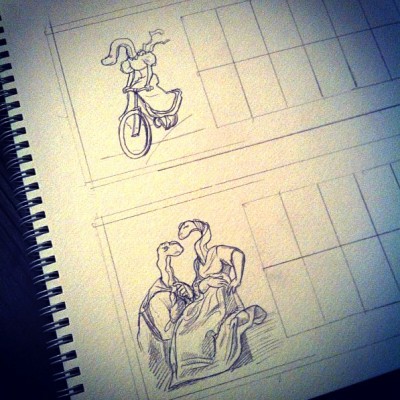

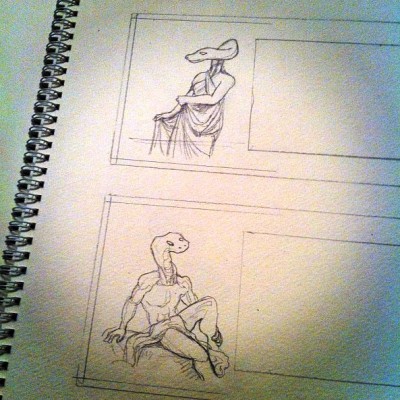

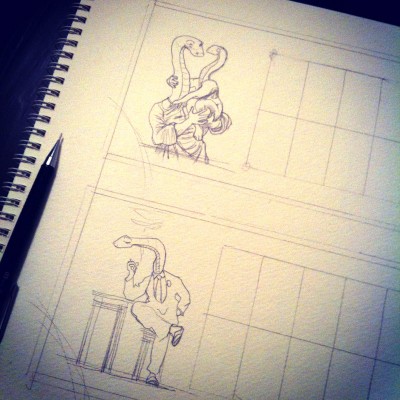

Drawing Gaxians

I drew twenty-nine cameo illustrations of Gaxian life in all its faceted wonder, trying to hew in tone toward the idyllic and classical. For the first time, I got to conceive of young and old Gaxians, Gaxians in different social roles, and in general different types of Gaxians distinct from our main friend Gax (this strip notwithstanding). I tried to give them a lot of individual character.

There are a few more in-progress pictures on my Instagram as well.

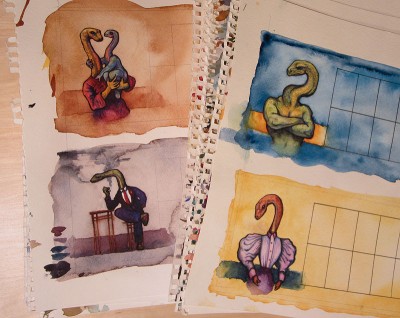

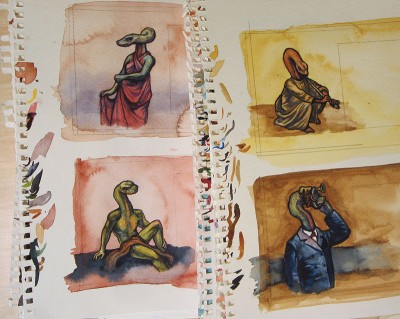

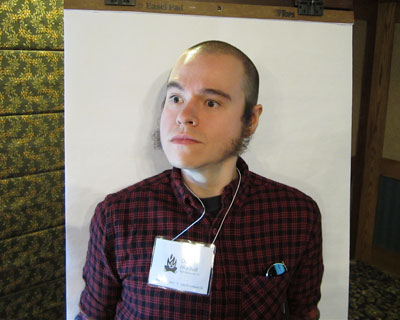

Now, for the coloring (which I knew would have to be spectactular), I knew I’d need help. So I enlisted the aid of Max Shepard.

Max is an illustrator and sculptor who worked with my wife Nikki in the puppet fabrication department at Robot Chicken. When their season ended and the show went on hiatus, I brought Max in to help out a bit in my office. As soon as I saw his painting skill I knew I had to collaborate with him in some more elaborate way.

I’m a very slow colorist and it doesn’t come intuitively to me, so I’m in awe of folks who can work with color skillfully. In fact, it was looking at Max’s portfolio that first gave me the idea that these Gax pieces could be hand-painted.

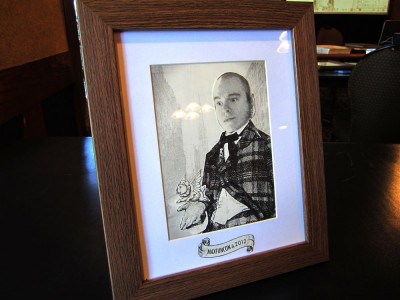

I think you’ll agree that he did a dynamite job! (Click any picture for a closer look)

Working just from my pencils, Max gave every piece a unique mood and distinct palette. I think they look super-great!!

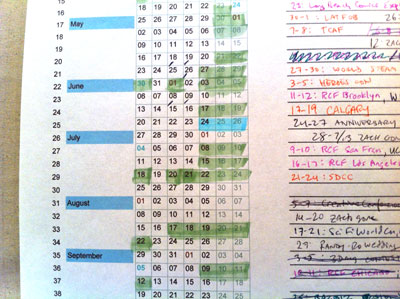

Now that we had all the images, regular collaborator Zachary Sigelko and I figured out which element of Gaxian life each piece was illustrating. (I also put them in chromatic order so the entire year becomes a beautiful rainbow. A bit ironic, since rainbows don’t exist on Gax!)

The result is a calendar that will inform and entertain you with a new piece of valuable information about the horrible Gaxian culture every other week! If you click the picture below you might be able to read a couple of them:

IN THE PACKAGE

Every calendar shipped will include:

• A pre-drilled backboard and four hooks

• An easel (if you select that you need one). Easel styles may vary from the picture depending on stock available.

• The 29 calendar cards, every set hand-signed and numbered by both me and Max.

• A Dick Van Patten Is Not At This Address sticker of course

At this point I estimate that the finished calendars will start shipping out this coming Friday.

I should also note that I am splitting the profits from these calendars with Max — it couldn’t have happened without his fantastic contribution. So by picking up a calendar you’re supporting both me and him!

This is very different from the previous calendars I’ve done, but I really, really love it and I hope you like it just as much. I don’t mind being honest with you — I did not know if this was going to work. At every step of the process I could only see a half-step ahead, like lighting a dark path with a flashlight. Could I do drawings I would be happy with? Would the paintings look okay? Could we fit any text on the long skinny cards? Would the backboard idea actually hold the cards? But this is how we do things, folks. This is how all of us do things. One step at a time, and sometimes you take a risk, and sometimes it comes out amazing. I’m happy to report that this is one of those times.

Checking the records now, as I write there are only 26 copies left unclaimed. If this is a thing you might like to have, please do not delay! UPDATE: They’re all gone! Thanks so much!